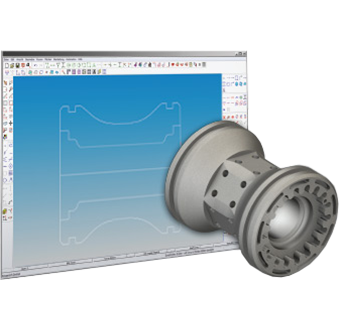

EZ-MILL

Robust data translators allow part models to be imported from virtually any CAD system, and powerful geometry extraction tools make prismatic machining from 3D data a simple task. EZ-CAM's unique integrated spreadsheet enables you to view all operation parameters at a glance, and the associative toolpath generation allows you to update your toolpaths with just a single click.

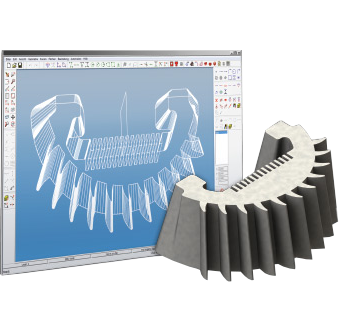

EZ-TURN

EZ-TURN also supports multiple spindles, turrets, and coordinate systems. Canned cycles can be used to increase efficiency and reduce program length. Fully integrated milling capabilities support both C and Y axis configurations and allow standard 2.5 axis milling operations to be performed on the face or wrapped around a specified diameter. Advanced verification displays both turning and milling together in a single environment, ensuring that any mistakes are caught before they reach the shop floor.

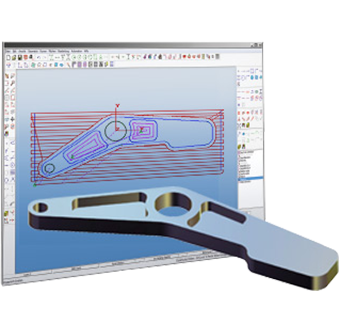

EZ-EDM

Convenient auto male/female part recognition plus access to every single wire movement via the motion record provides full control of taper and wire compensation registers at all times. The proven geometry interface now imports solids and surface models via IGES and STL. Extensive 3D surface creation and editing functions like the new Extract Cross Section command drastically ease the task of creating the Machining curves.

EZ-MILL Pro

3D Surface Machining Wizard combines 12 different Roughing, Re-Roughing and Finishing strategies under a new and simple-to-use dialog box.

EZ-MILL Express

The powerful geometry construction tools are easy to learn and use, and multiple import/export options including DXF and IGES allow existing CAD systems to be readily companioned.

EZ-Turn Express

The powerful geometry construction tools are easy to learn and use, and multiple import/export options including DXF and IGES allow existing CAD systems to be readily companioned.

FilterMAX

Small linear moves can slow down a CNC Control's processing time significantly, arc moves generated by FilterMAX eliminate this delay allowing the machine to run much faster.

Alibre

3D modelling for mechanical systems is the core competency of Alibre Design. Create complex parts from scratch or by using existing or imported parts as a reference. Assemble them together to create a final product, and evaluate the physical and motion characteristics.

Enjoy permanent licenses and buy optional updates when you like. You can easily move your license between computers. Keep your data wherever you want and never lose access to your files.

Contact us for an obligation free Quotation.